Extend the life of your metal roof at a lower cost than a full replacement. Get the project done fast with fabric-less roof coating systems

- Longest performing system in the industry

- Polyurethane fabric-less seam sealer since 1977

- System bends and stretches with roof

- Less disruption for your business

Metal expands and contract backing out fasteners, neoprene washers become brittle causing them to fail, and rust can form weakening the panel.

Use ERSystems metal restoration coating technology to address deficiencies and bring your roof to as good as or better than new condition.

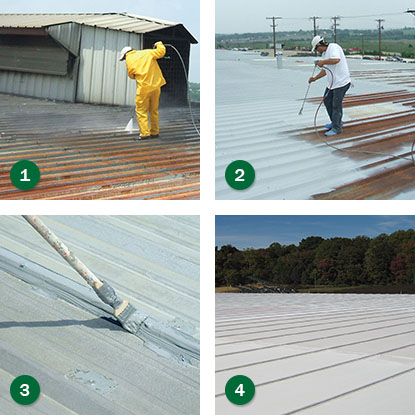

Before & After Photos

Process

1. Prepare the roof. Prep and clean the roof, removing dirt and debris. Ensure that roof is properly prepared – tightening and replacing fasteners, and ensuring that seams are stitched tight. Seams with gaps larger than ¼” need to caulked with Permathane® SM7120 PU then stitch screwed.

2. Prime (if necessary) all rust with our rust inhibiting primer – Acrylic Metal Rust Primer or Polyurethane Metal Rust Primer – to halt the rust and to prevent more rust from forming.

3. Seal. H.E.R. Polyurethane Sealant is applied to the seams, fasteners and penetrations and then smoothed with a brush. H.E.R. will provide 60mils of polyurethane protection. since it’s a fabric-less product, it avoids trapping water which can be a point of failure on other restoration systems.

4. Preserve. As the final layer of protection, apply 2 coats of highly reflective Acrylic 1000 Plus/Acrylic SW. It provides a weather resistant, seamless sacrificial barrier that will significantly reduce the harmful effects and damage caused by UV rays.

Benefits

- Reduce energy costs

- Slow the aging process

- Decrease future maintenance cost

- Change the life cycle of the roof